Everything You Need to Know About Fresh Water Cooled Exhaust Manifolds Marine for BBC

The marine engine sector has undergone remarkable advancements, with cutting-edge technologies consistently enhancing engine performance, durability, and fuel efficiency. A standout innovation in the field is the use of fresh water cooled exhaust manifolds, especially in Big Block Chevy (BBC) engines. These components are vital in maintaining engine efficiency, reducing the frequency of repairs, and extending the life of the engine.

In this guide, we will delve into the functionality of fresh water cooled exhaust manifolds, their importance for marine engines, particularly BBC engines, and the key benefits they provide.

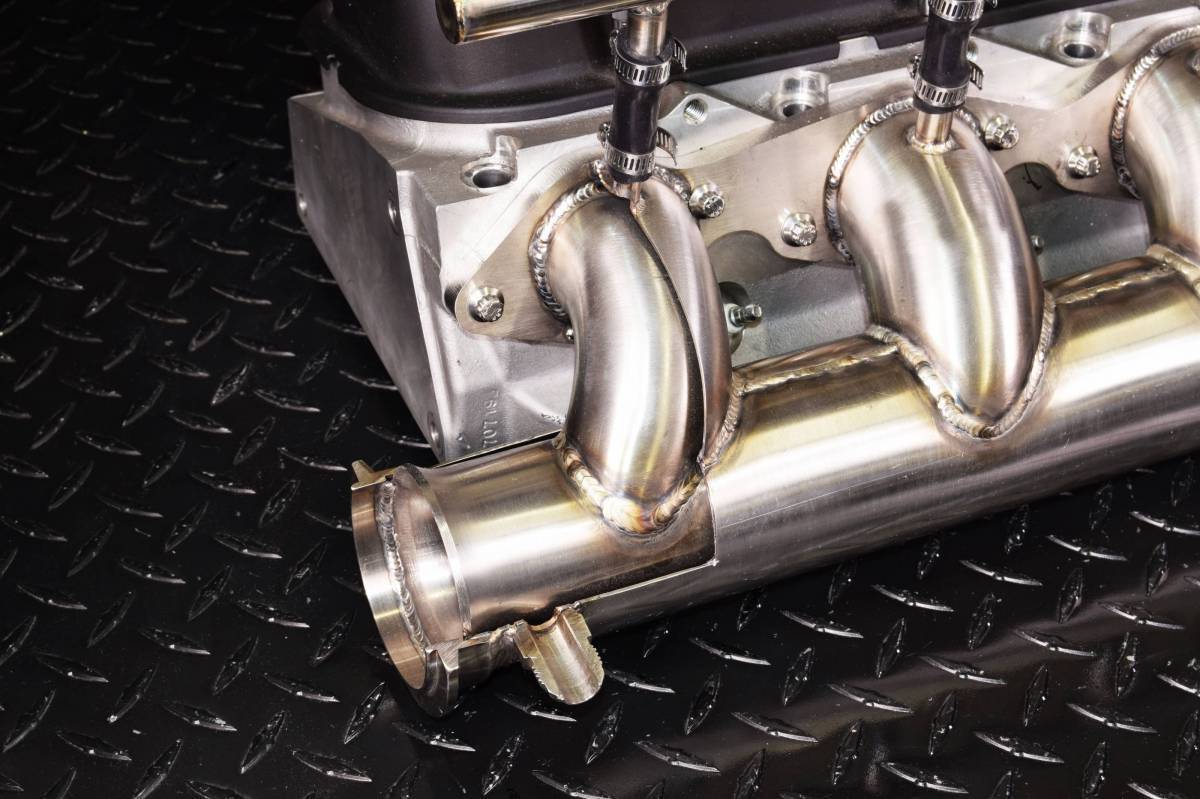

What Are Fresh Water Cooled Exhaust Manifolds Marine for BBC?

Fresh water cooled exhaust manifolds are an integral part of the cooling system in marine engines. Their primary role is to cool the exhaust gases produced by the engine, ensuring the engine doesn’t overheat. In this setup, “fresh water” refers to the coolant circulating through the manifold, which is usually a mix of antifreeze and water, unlike the raw seawater typically used in conventional cooling systems.

These manifolds operate alongside the engine’s main cooling system. In contrast to traditional exhaust manifolds that directly use seawater, fresh water cooled exhaust manifolds employ a closed-loop system. This means the coolant stays separate from both the exhaust gases and seawater, providing more stable engine temperatures and preventing the issues associated with saltwater, such as rust and corrosion.

For BBC marine engines, these manifolds are essential for maintaining engine performance and durability, offering improved protection against the harsh conditions of the marine environment.

How Do Fresh Water Cooled Exhaust Manifolds for BBC Marine Engines Function?

The process by which fresh water cooled exhaust manifolds work is straightforward:

- Exhaust Gas Flow: As the BBC engine runs, exhaust gases pass through the exhaust manifold, where they are extremely hot. Without cooling, these gases could cause the engine to overheat.

- Cooling the Gases: The manifold is equipped with a water jacket that surrounds the exhaust. Fresh water, typically a mixture of antifreeze and water, circulates through this jacket, absorbing heat from the exhaust gases.

- Heat Transfer: The coolant absorbs the heat from the exhaust gases, preventing overheating of the manifold and the engine.

- Heat Dissipation: After absorbing the heat, the coolant flows to a heat exchanger or another cooling component, where it is cooled before being pumped back through the system. This cycle keeps exhaust temperatures under control.

- Corrosion Prevention: The closed-loop system in BBC marine engines protects the exhaust manifolds from corrosion by keeping seawater away from sensitive engine components, ensuring their longevity.

Why Are Fresh Water Cooled Exhaust Manifolds Crucial for Marine Engines?

- Efficient Cooling: Marine engines, particularly high-performance models like BBC engines, generate significant heat. Fresh water cooled exhaust manifolds offer more efficient cooling compared to traditional raw-water systems, which is especially important for high-output engines.

- Preventing Overheating: Overheating can severely damage marine engines. By maintaining an optimal engine temperature, fresh water cooled exhaust manifolds help minimize the risk of overheating, preserving engine health.

- Longer Engine Lifespan: Constant exposure to seawater can lead to rust and corrosion, which accelerates wear and tear on engine parts. Fresh water cooled exhaust manifolds help protect BBC engines from these harsh conditions, leading to an extended engine lifespan.

- Lower Maintenance Needs: Since fresh water cooled manifolds use a closed-loop system, the frequency of repairs and the need for constant maintenance are reduced. This also limits the exposure to raw seawater, which can cause scaling and corrosion.

- Improved Fuel Efficiency: A well-cooled engine operates more efficiently, consuming less fuel and emitting fewer pollutants. The fresh water cooling system helps the engine run at peak efficiency, contributing to better fuel economy.

Key Advantages of Fresh Water Cooled Exhaust Manifolds for BBC Engines

- Corrosion Resistance: Seawater is corrosive, which can damage engine components over time. Fresh water cooled exhaust manifolds mitigate this risk by using fresh water, enhancing the longevity of the engine parts.

- Enhanced Cooling Performance: Fresh water is a more effective coolant than seawater because it maintains a more stable temperature. This improves heat dissipation, which is particularly crucial for high-performance BBC engines operating at elevated temperatures.

- Extended Engine Life: Fresh water cooling protects against the detrimental effects of seawater, including rust and scaling. This reduces the likelihood of engine failure and ensures a longer operational life.

- Efficient Heat Management: Fresh water systems are generally better at transferring heat compared to seawater systems. These cooling systems are designed to handle high heat loads, which makes them ideal for powerful BBC engines.

- Cleaner Exhaust System: Unlike raw water systems, which can sometimes lead to algae buildup and debris blockages, fresh water cooling helps keep the exhaust system cleaner and free from contaminants, contributing to better engine performance.

- Environmental Benefits: By reducing the reliance on raw seawater, fresh water cooled exhaust manifolds minimize the environmental impact of marine engines. This system ensures more efficient and cleaner engine operation, with less risk of discharging untreated seawater into the ocean.

Maintaining Fresh Water Cooled Exhaust Manifolds

While fresh water cooled exhaust manifolds reduce maintenance compared to raw-water systems, they still require some care to ensure optimal performance. Here are some essential maintenance tips:

- Regular Coolant Checks: Ensure the coolant is at the correct level and inspect it for signs of contamination, such as discoloration. Replace the coolant as necessary to maintain effective heat transfer.

- Leak Inspections: Over time, manifolds may develop leaks due to wear or corrosion. Regularly inspect for signs of coolant or exhaust gas leaks and address any issues promptly to avoid engine damage.

- System Flushing: Periodically flush the cooling system to eliminate any debris or contaminants that might affect performance. This ensures the system continues to function properly.

- Heat Exchanger Maintenance: The heat exchanger is crucial for cooling the coolant. Inspect it regularly to ensure it’s clean and unobstructed, as blockages can impair cooling efficiency.

- Exhaust System Inspections: Examine the exhaust system for signs of corrosion or debris buildup. Keeping the exhaust manifold clear helps maintain overall system performance.

Key Facts about Fresh Water Cooled Exhaust Manifolds Marine for BBC

- Cooling Efficiency: Fresh water cooled exhaust manifolds use a closed-loop cooling system, where fresh water (typically a mixture of antifreeze and water) absorbs the heat from the exhaust gases. This is more efficient than using raw seawater.

- Corrosion Resistance: These manifolds help protect marine engines, especially BBC engines, from the corrosive effects of seawater. The system keeps seawater away from the exhaust manifold, reducing the risk of rust and deterioration.

- Engine Longevity: By maintaining optimal temperatures and preventing corrosion, fresh water cooled exhaust manifolds can significantly extend the life of marine engines, including Big Block Chevy (BBC) engines.

- Improved Engine Performance: These manifolds ensure that the engine remains cool and runs at peak performance. They prevent overheating, which is crucial for high-performance engines like BBCs.

- Maintenance Reduction: Fresh water cooled exhaust manifolds reduce the frequency of maintenance compared to raw-water cooled systems. The closed-loop system minimizes exposure to contaminants, reducing wear and tear on components.

- Environmental Impact: By reducing the need for raw seawater in the cooling system, these manifolds help lower the environmental impact of marine engines, preventing the discharge of untreated seawater into the ecosystem

Conclusion: The Value of Fresh Water Cooled Exhaust Manifolds for BBC Marine Engines

Fresh water cooled exhaust manifolds are a crucial component in ensuring the proper functioning and longevity of marine engines, particularly for Big Block Chevy (BBC) engines. The closed-loop cooling system provides superior benefits over traditional raw-water systems, offering better heat management, corrosion resistance, and less maintenance. As the marine industry continues to prioritize engine performance and environmental protection, the adoption of fresh water cooled exhaust manifolds is on the rise, benefiting both boaters and marine engine enthusiasts alike..

FAQs about Fresh Water Cooled Exhaust Manifolds Marine for BBC

1. What are Fresh Water Cooled Exhaust Manifolds Marine for BBC?

Fresh water cooled exhaust manifolds are cooling system components that prevent engine overheating by circulating fresh water (usually a mixture of antifreeze and water) around the exhaust gases. This ensures that the engine operates within safe temperature ranges and reduces corrosion compared to raw-water cooling systems.

2. Why are Fresh Water Cooled Exhaust Manifolds important for BBC engines?

BBC engines are high-performance engines that generate a lot of heat. Fresh water cooled exhaust manifolds are essential for maintaining optimal engine temperatures, preventing overheating, and extending the life of the engine by reducing exposure to corrosive seawater.

3. How do Fresh Water Cooled Exhaust Manifolds work?

These manifolds use a closed-loop system in which fresh water circulates through a water jacket surrounding the exhaust gases. The coolant absorbs heat from the gases, preventing the engine and exhaust components from overheating. The heated coolant is then cooled by a heat exchanger before being recirculated.

4. What are the advantages of using Fresh Water Cooled Exhaust Manifolds for BBC engines?

The key benefits include better heat dissipation, protection against corrosion, longer engine lifespan, reduced maintenance requirements, and improved fuel efficiency. Fresh water cooling also helps maintain engine performance, especially in high-output BBC engines.

5. How do Fresh Water Cooled Exhaust Manifolds prevent corrosion?

The closed-loop system in fresh water cooled exhaust manifolds prevents seawater from coming into direct contact with critical engine components. This reduces the chances of rust and corrosion that are common when using raw seawater.

6. Do Fresh Water Cooled Exhaust Manifolds require maintenance?

Yes, while they require less maintenance than raw-water cooled systems, it’s still essential to check coolant levels, inspect for leaks, flush the cooling system periodically, and maintain the heat exchanger to ensure the system operates efficiently.

7. Are Fresh Water Cooled Exhaust Manifolds more efficient than raw-water systems?

Yes, fresh water cooled exhaust manifolds are generally more efficient at cooling and heat dissipation. Fresh water can maintain a more consistent temperature compared to seawater, which is beneficial for high-performance marine engines like BBCs.

8. Can Fresh Water Cooled Exhaust Manifolds be used in any marine engine?

While fresh water cooled exhaust manifolds are common in high-performance marine engines, especially BBCs, they can be used in other marine engines as well. However, they may be most beneficial in engines that run in harsh saltwater environments.

9. How does the use of Fresh Water Cooled Exhaust Manifolds impact engine fuel efficiency?

Since these manifolds help maintain optimal engine temperatures and reduce wear, they can lead to better engine efficiency, improved fuel economy, and reduced emissions.

10. Can Fresh Water Cooled Exhaust Manifolds be installed as an upgrade for existing systems?

Yes, it is possible to upgrade an existing raw-water cooling system to a fresh water cooled exhaust manifold system. However, the installation may require additional components like heat exchangers and coolant circulation systems.

Stay updated with the latest news and trends here at My Reading Manga!