Your Complete Guide to the Simmons 4 Inch Well Seal Maintenance Port Diagram: Installation and Maintenance Explained

Overview of the Simmons 4-Inch Well Seal with Maintenance Port

A well seal plays a crucial role in maintaining the integrity and cleanliness of a water well. Its primary function is to cover the top of the well casing, safeguarding the water from contaminants like dirt, insects, and other foreign materials. This barrier ensures the water remains safe for use.

The Simmons 4-inch well seal, featuring an integrated maintenance port, is a highly trusted component in water well systems. Designed to fit 4-inch well casings, this well seal is suitable for both residential and commercial applications. Known for its durable construction, Simmons is a reputable brand offering high-quality well parts. One of the key advantages of this model is its maintenance port, which allows for easy inspection and minor maintenance tasks without the need to remove the entire seal, thus saving time and ensuring the well continues to operate smoothly.

Constructed from robust materials, the Simmons 4-inch well seal is built to last for years. Its design ensures a secure fit around the well casing, providing protection for the water supply and giving well owners peace of mind.

The Role and Function of Well Seals

Well seals are critical to a well’s performance, ensuring that the water remains free from contamination. Their primary function is to block unwanted substances such as dirt, insects, and chemicals from entering the well by covering the top of the casing. Without a proper seal, a well could easily become compromised, leading to unsafe water.

The Simmons 4-inch well seal with a maintenance port is designed not only to protect the well from external contaminants but also to facilitate regular check-ups and repairs. This maintenance port is a small opening that enables quick inspections and minor fixes without needing to dismantle the entire seal. This feature helps maintain the well’s health and prevents larger, more costly problems.

In addition to protecting the water supply, well seals also shield the well’s pump and other components. By preventing leaks, a seal helps maintain balanced pressure within the system. A tightly fitted seal, such as the Simmons 4-inch model, contributes to better performance and a longer-lasting water system.

To ensure the well remains safe and operational, it’s vital to regularly check and maintain the seal. A loose or damaged seal can let bacteria and other contaminants into the water, making it unsafe for use. Routine inspections and upkeep of the Simmons 4-inch well seal with maintenance port help keep both the water quality and the system’s functionality intact.

Key Characteristics of the Simmons 4-Inch Well Seal

The Simmons 4-inch well seal with maintenance port is engineered for both durability and user-friendliness. With a range of features designed to protect and streamline well maintenance, it is an excellent choice for safeguarding your water well.

High-Quality Materials for Durability

The Simmons 4-inch well seal is crafted using premium materials like cast iron, steel, and ABS plastic. These materials are resistant to rust, corrosion, and wear, making the seal highly durable even under harsh environmental conditions. Its solid build ensures the well remains securely sealed and the water supply protected over time.

Versatile and Practical Design

The design of the Simmons well seal strikes a balance between strength and flexibility. It features either a split or solid top plate, each offering distinct advantages:

- The split top plate makes installation easier by allowing the seal to fit around existing pipes without needing to disconnect them.

- The solid top plate, on the other hand, provides a tighter, more secure seal for maximum protection.

This well seal is also adaptable to various drop pipe sizes, making it suitable for a wide range of well systems.

Convenient Maintenance Port for Easy Access

A standout feature of the Simmons 4-inch well seal is its built-in maintenance port. This small opening allows for quick inspections, pressure checks, and minor repairs without removing the seal. It facilitates easier upkeep of the well system, saving time and effort while maintaining the well’s proper function.

Breakdown of the Simmons 4-Inch Well Seal with Maintenance Port

Understanding the different components of the Simmons 4-inch well seal with maintenance port helps explain how it works to protect your water system. Each part is designed to contribute to a secure and effective seal that ensures your well stays clean and functional.

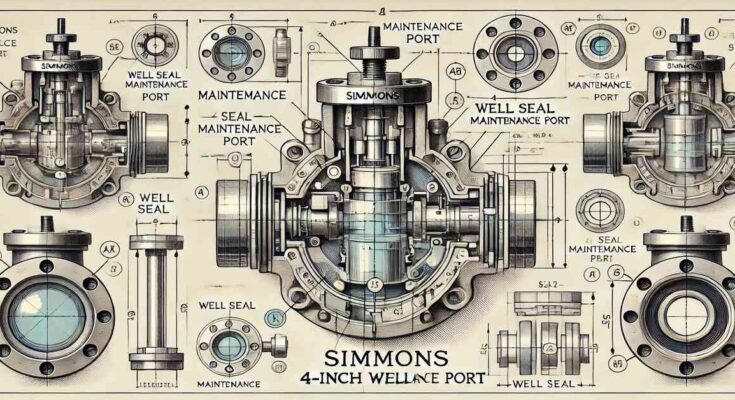

Visual Diagram of the Simmons 4-Inch Well Seal

The diagram of the Simmons 4-inch well seal offers a clear depiction of its parts and how they fit together to form a tight seal on the well casing. It highlights labeled components like the upper and lower plates, gaskets, bolts, and the maintenance port, which collectively work to ensure the seal’s effectiveness.

Identification of Key Components

- Upper Plate

The top section of the seal, available in either a split or solid design. This plate covers the casing and holds the drop pipe, providing a barrier against contaminants.

- Lower Plate

Located inside the casing, the lower plate works with the upper plate to create a secure, leak-proof seal.

- Gaskets

Made from rubber or neoprene, these are placed between the plates to prevent leaks and keep out dirt, insects, and water from the outside.

- Bolts and Nuts

Used to secure the upper and lower plates together. Tightening the bolts compresses the gaskets, strengthening the seal.

- Maintenance Port

A small opening in the upper plate, which allows for easy access to the well for pressure checks, inspections, and minor repairs.

How Each Component Contributes to the Seal’s Functionality

The upper and lower plates work in tandem to create a tight, protective seal around the well casing. The gaskets provide a flexible yet firm barrier that fills any gaps, preventing leaks. Bolts and nuts hold everything together, ensuring a secure fit. The maintenance port adds convenience by allowing easy access for maintenance tasks without the need to remove the entire seal.

Installing the Simmons 4-Inch Well Seal with Maintenance Port

Proper installation of the Simmons 4-inch well seal is essential for ensuring the well’s protection and efficient operation. Following the correct steps guarantees a secure, long-lasting fit.

Installation Steps for Optimal Fit

- Prepare the Well Casing and Seal Components

- Clean the well casing to remove any dirt, rust, or debris.

- Check the well seal to ensure no parts are missing or damaged.

- Position the Lower Plate:

- Slide the lower plate into the casing and center it for an even seal.

- Insert the Drop Pipe:

- Position the drop pipe through the opening in the upper plate, ensuring it fits securely.

- Align the Upper Plate:

- Place the upper plate over the well casing and align it with the lower plate.

- Tighten the Bolts and Nuts:

- Use a wrench to tighten the bolts evenly in a crisscross pattern, compressing the gaskets for a firm seal.

- Check the Maintenance Port:

- Ensure the maintenance port cap is tightly secured to prevent contamination.

- Final Inspection:

- Check for any gaps or loose fittings to ensure the seal is tight.

Common Installation Mistakes to Avoid

- Over-tightening Bolts:

- Excessive tightening can damage the gaskets. Tighten the bolts moderately and evenly.

- Misaligned Plates:

- Ensure the upper and lower plates are aligned properly to prevent leaks.

- Dirty or Damaged Gaskets:

- Always inspect gaskets before installation to ensure they’re in good condition.

- Neglecting the Maintenance Port:

- Ensure the maintenance port cap is secure to avoid contamination.

Regular Maintenance of the Simmons 4-Inch Well Seal

Maintaining the Simmons 4-inch well seal with maintenance port is vital for preserving the well’s cleanliness and ensuring efficient performance. Regular inspections and timely repairs will help avoid larger issues and extend the seal’s lifespan.

Routine Inspection and Upkeep

- Monthly Visual Inspections:

- Look for visible damage like cracks, rust, or loose bolts.

- Gasket Checks:

- Inspect gaskets every six months for wear or damage.

- Bolt Tightness:

- Tighten bolts quarterly to ensure the seal remains secure.

- Surface Cleaning:

- Clean the seal surface semi-annually to remove dirt, debris, or corrosion.

Using the Maintenance Port for Inspections and Repairs

The maintenance port simplifies inspections and repairs:

- Water Level Monitoring:

- Use the port to check the water level without removing the seal.

- Pressure Testing:

- Perform pressure checks through the port to ensure the system is balanced.

- Chemical Treatments:

- Add disinfectants or treatment solutions directly through the port.

- Ventilation Checks:

- Ensure the port is clear and sealed when not in use to prevent contaminants from entering.

When to Replace Seal Components

- Worn Gaskets:

- Replace gaskets if they show signs of cracking or flattening.

- Corroded Parts:

- Replace rusted or damaged plates and bolts to maintain the seal’s integrity.

- Loose or Damaged Maintenance Port Cap:

- A damaged cap needs immediate replacement to prevent contamination.

Troubleshooting Common Seal Issues

Even with regular maintenance, issues can arise with the Simmons 4-inch well seal. Identifying and addressing problems early helps prevent further damage.

Common Problems and Solutions

- Leaks:

- Check for pooling water around the seal or damp areas. Tighten bolts or replace damaged gaskets if necessary.

- Corrosion:

- Clean rusted areas and apply a rust-resistant coating to prevent further degradation.

- Pressure Imbalance:

- If there are issues with pressure, inspect the maintenance port for blockages and ensure proper ventilation.

Key Facts

Primary Function: The Simmons 4 Inch Well Seal with Maintenance Port is designed to prevent contamination in water wells by blocking dirt, debris, insects, and harmful materials from entering the well system. It ensures the water remains safe and clean.

Maintenance Port: A unique feature of this well seal is the integrated maintenance port, which allows for easy inspection, pressure testing, and minor repairs without the need to remove the entire seal. This helps in maintaining the well system efficiently and saves time.

Durable Construction: The Simmons 4 Inch Well Seal is made from strong materials like cast iron, steel, and ABS plastic, which resist rust, corrosion, and wear, making it ideal for long-term use in harsh environments.

Design Flexibility: The seal is designed to be adaptable, with options such as a split or solid top plate for easier installation. It fits well with a variety of drop pipe sizes and types, including PVC, steel, and galvanized pipes.

Easy Installation: The installation of the Simmons 4 Inch Well Seal with Maintenance Port is straightforward, requiring careful positioning of the plates, gaskets, and drop pipe. Tightening the bolts in a crisscross pattern ensures a secure seal.

Maintenance Requirements: Regular maintenance includes checking for wear on gaskets, tightening bolts, and cleaning the seal surface. The maintenance port makes it easier to inspect the well system without having to fully remove the seal.

Common Troubleshooting: Issues like leaks, loose bolts, or misaligned plates can be detected through visual inspections. The maintenance port allows quick fixes and ensures that the well seal remains functional.

Long-Term Benefits: Proper sealing helps prevent contamination and minimizes system wear, which extends the life of the well and reduces maintenance costs over time.

Customization Options: Simmons offers custom well seals for specific well systems. These custom options can include different gasket materials, port sizes, and corrosion-resistant coatings.

Compatibility: The Simmons 4 Inch Well Seal is compatible with both submersible and jet pumps and works with various well systems, providing flexibility for residential and commercial applications.

Conclusion

The Simmons 4-inch well seal with maintenance port is a vital component of any well system. It provides an effective barrier against contamination, supports water quality, and enhances the overall efficiency of the well. With its durable construction and user-friendly design, it is ideal for both residential and commercial use.

To ensure the best performance, proper installation and ongoing maintenance are key. Regular inspections, prompt repairs, and careful use of the maintenance port can prevent contamination, leaks, and costly repairs, thereby extending the lifespan of the well system.

FAQs

- What does the maintenance port on the Simmons 4-inch well seal do?

The maintenance port provides easy access for inspections, pressure checks, and minor repairs without removing the seal. - How often should I check my Simmons 4-inch well seal?

It’s recommended to inspect the well seal every 3 to 6 months to catch any early signs of damage. - Can I install the Simmons 4-inch well seal myself?

Yes, the seal is designed for DIY installation, but it’s important to follow the manufacturer’s guidelines for the best results. - When should I replace the well seal?

If you notice cracks, leaks, or damaged gaskets, it may be time to replace the seal or its components. - Is the Simmons 4-inch well seal compatible with all pumps?

Yes, it works with most submersible and jet pumps and accommodates various pipe materials.

Stay updated with the latest news and trends here at My Reading Manga!